In today’s rapidly evolving business landscape, the integration of cutting-edge technology has become paramount for sustained growth and efficiency. One such technological marvel making waves in various industries is the collaborative robot, often referred to as a cobot. These intelligent robots are revolutionizing the way businesses operate, offering a myriad of benefits from increased productivity to enhanced safety measures.

Evolution of Collaborative Robots

Historical Background

Collaborative robots have a rich history, stemming from the early developments in robotics during the mid-20th century. However, their true potential started to unfold in the past decade with significant advancements in sensors, artificial intelligence, and human-machine interfaces.

Technological Advancements

The rapid pace of technological progress has fueled the evolution of collaborative robots. Advanced sensors, including vision systems and force sensors, enable cobots to work alongside humans safely. The integration of machine learning algorithms has further enhanced their adaptability and decision-making capabilities.

Current Market Trends

The global market for collaborative robots is experiencing exponential growth. Industries such as manufacturing, healthcare, and logistics are increasingly adopting cobots to streamline operations and stay competitive. The market is projected to witness continued expansion as more businesses recognize the value of these intelligent robotic companions.

Key Features of Collaborative Robots

Flexibility

Collaborative robots are designed to be flexible and easily adaptable to changing tasks and environments. Unlike traditional industrial robots confined to cages, cobots can work side by side with human workers, facilitating seamless collaboration.

Safety Mechanisms

Ensuring the safety of human workers is a top priority in any workplace. Collaborative robots come equipped with advanced safety features, such as force-limiting technology and intuitive programming interfaces, making them inherently safe for coexistence with humans.

Human-Robot Interaction

The success of collaborative robots lies in their ability to interact with humans in a natural and intuitive manner. This fosters a collaborative work environment where humans and robots complement each other’s strengths, leading to increased overall productivity.

Applications in Different Industries

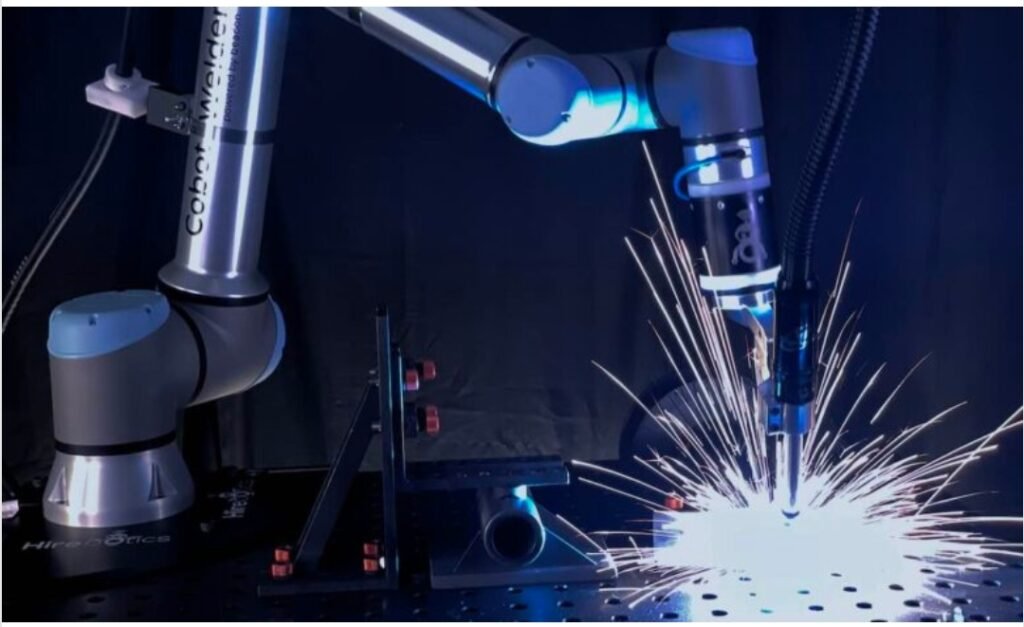

Manufacturing

In the manufacturing sector, collaborative robots are transforming assembly lines. They excel in tasks that require precision and repetition, allowing human workers to focus on more complex and creative aspects of production.

Healthcare

Collaborative robots are finding applications in healthcare, assisting medical professionals in tasks such as surgery, patient care, and medication dispensing. Their precision and ability to operate in confined spaces make them invaluable in medical settings.

Logistics

Streamlining warehouse operations and optimizing logistics processes are areas where collaborative robots are proving their worth. They can efficiently handle tasks such as picking and packing, reducing the time and effort required for these activities.

Advantages of Incorporating Collaborative Robots

Increased Efficiency

Collaborative robots enhance efficiency by automating repetitive tasks, allowing human workers to focus on tasks that require creativity and critical thinking. This results in a significant boost in overall productivity.

Cost Savings

While the initial investment in collaborative robots may seem substantial, the long-term cost savings are undeniable. Reduced operational costs, increased output, and minimized errors contribute to a favorable return on investment.

Enhanced Workplace Safety

The integration of collaborative robots significantly reduces the risk of workplace accidents. With advanced safety features and the ability to work alongside humans without safety barriers, cobots contribute to a safer working environment.

Challenges and Solutions

Technical Challenges

The implementation of collaborative robots comes with its share of technical challenges, including programming complexities and system integration issues. However, ongoing advancements in robotics technology and increased support from manufacturers are addressing these challenges.

Workforce Adaptation

Introducing collaborative robots into the workforce requires a certain level of adaptation from human workers. Providing adequate training and fostering a culture of collaboration can overcome resistance and ensure a smooth transition.

Industry-Specific Challenges

Different industries face unique challenges when implementing collaborative robots. Understanding and addressing these challenges on a case-by-case basis is crucial for successful integration.

How Collaborative Robots Can Boost Business Productivity

Automation of Repetitive Tasks

Collaborative robots excel in automating repetitive and mundane tasks, allowing human workers to focus on tasks that require creativity, problem-solving, and decision-making skills.

Precision and Accuracy

The precision and accuracy of collaborative robots make them ideal for tasks that demand a high level of accuracy, such as assembly, quality control, and inspection processes.

Accelerated Production Timelines

By working seamlessly with human workers, collaborative robots contribute to faster production timelines. The combination of human ingenuity and robotic efficiency results in accelerated and more streamlined production processes.

Real-Life Success Stories

Companies Embracing Collaborative Robots

Leading companies across various industries are reaping the benefits of collaborative robots. From automotive manufacturing to healthcare, examples abound of businesses successfully integrating cobots into their operations.

Positive Impacts on Operations

Businesses report positive impacts on operational efficiency, product quality, and overall output after incorporating